To learn more about RIVNUT® (rivet nut) fasteners, please refer to a sampling of options below! Should you want to explore rivet nuts based on part numbers, we have a fantastic reference guide.

CLOSED END RIVET NUT INSTALL

Not what you’re looking for? Call us or check out our Install Tools page for more information.

CLOSED END RIVET NUT MANUAL

we offer pull-to-pressure, pull-to-stroke, and battery-operated pull-to-pressure pneumatic nut insert tools (such as our 4090, B4090 & 6703) and manual hand tools ( C845, C722, C6000 & 140-2000). Productivity gains are facilitated by the ease of installation, which occurs via the selection of installation tools that Rivet Nut USA has tested and has AVAILABLE NOW for easy-to-use and reliable rivet nut installation. The rivet nut offers productivity gains over nearly every other fastener alternative (weld nuts, nut and bolts, press in inserts, etc.). When needing to mate a secondary attachment to the parent application, the rivet nut is the go-to fastener for manufacturers in all industries, including automotive, appliance, food equipment, and aerospace. These fasteners can be installed into dissimilar materials and certain rivet nuts offer internal rolled threads for increased thread strength. RIVNUTS® generally have a tapered shank for automation and hole insertion ease. Round body rivet nuts can offer a special feature of a fully cold-formed, externally knurled body for increased spin-out resistance, or an external “key” feature under the head that locks into its “keyhole” for even better spin-out resistance, or look to a hex body rivet nut for superior best-of-class spin-out resistance. Internally threaded rivet nuts are typically available in aluminum, steel, and stainless steel (sometimes, brass). Size not listed? Please make an enquiry – we may be able to provide it.Rivet nuts require no finishing work and solve even the most challenging fastening problems.

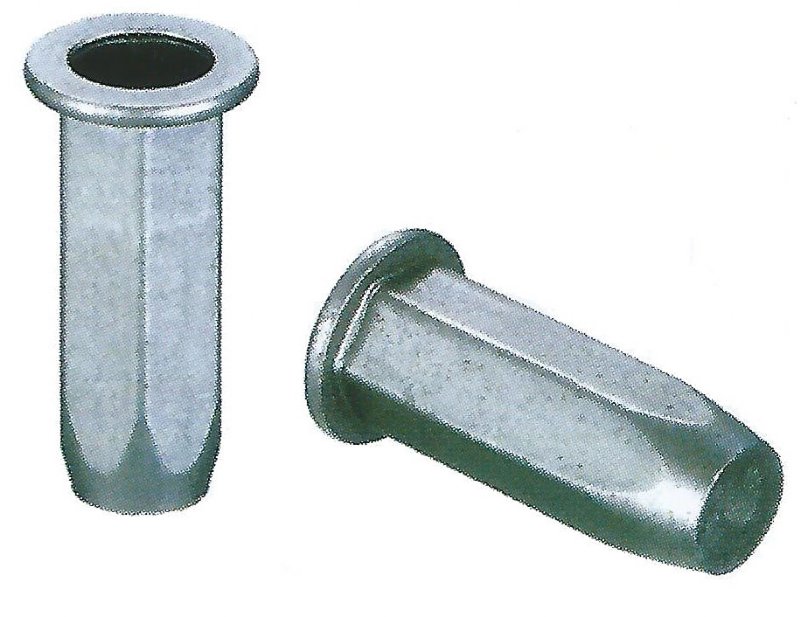

= Zinc Plated Steel // = A2 Stainless Steel // = A4 Stainless Steel Non-standard sizes and materials are available to order as specials, including small volume manufacture, modifications and bespoke parts made to drawings. Rivet Nut Countersunk Knurled Closed End are available in diameters from M3 to M12 to suit various grip ranges.Īvailable at Fastenright in Zinc Plated Steel, A2 Stainless Steel and A4 Stainless Steel as standard.

Installing these rivet nuts is simple, using a special tool with a threaded stud, or nose, that engages with the internal threads of the rivet nut and pulls upwards, deforming the unthreaded section of the rivet nut to expand under the reverse side of the material – providing a high strength permanent thread in a thin sheet material. The closed-end blocks any form of contamination getting to the component, and also prevents the use of screws that are too long for the application.

The presence of the knurled body on the rivet nut provides greater resistance to movement within the application than knurling under the head, especially when installed in softer materials. Both types offer a flush, finished appearance to the application. Where the thickness of the application is smaller, the reduced countersunk type is often chosen instead.

CLOSED END RIVET NUT FULL

The full countersunk head is chosen over a reduced countersunk head type due to its stronger nature, however it is also deeper, meaning that it can only be used in material thicknesses greater than 1.5mm. Rivet Nut Countersunk Knurled Closed End, also referred to as Rivnuts, Blind Nuts and Nutserts®, are an internally threaded insert often used when the thickness of the application at hand is too small to tap a standard thread.īy using rivet nuts, a strong thread is created in thin sheets of material, for high strength fastening from bolts and other threaded articles.

0 kommentar(er)

0 kommentar(er)